Label Film Wrap Around Label, White, High Speed

HST-1(PLO) LB HS

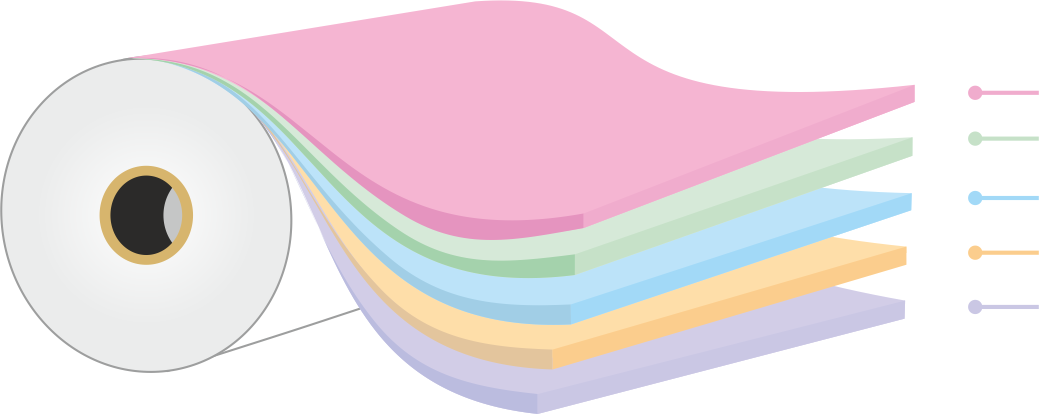

Structure

Treated, glossy Printable layer

Inter layer

Cavitated white pigmented OPP core

Inter layer

Untreated glossy layer

Description

It is a co-extruded, both sides heat sealable and one side treated cavitated white opaque Bi-axially Oriented Polypropylene film.

Features

- Excellent machinability

- High gloss and opacity

- Printable with solvent based ink

- Low density and high yield

- Good antistatic

Applications

- Wrap around labels for containers of soft drinks, mineral water etc.

Typical values

| Properties | Ref. | Units | ASTM#/ Test Method | HST-1(PLO) LB HS |

|---|

| Physical Data | ||||

| Average Thickness | Micron | D-374-C | 38 | |

| Gauge | 152 | |||

| Mils | 1.5 | |||

| Thickness Variation | %(±) | 5 | ||

| Average substance | g/m² | 25.8 | ||

| Density | g/cc | 0.68 | ||

| Surface Tension(min) | dynes/cm | D-2578 | 38 | |

| Kinetic COF | UT-UT | D-1894 | 0.20-0.35 | |

| Yield | m²/Kg | D-4321 | 38.7 | |

| Optical Data | ||||

| Gloss (45⁰) | Treated side | Gardner | D-2457 | >80 |

| Opacity | % | Hunter Lab D25-2CR | >70 | |

| Whiteness Index | % | E-313 | >90 | |

| Mechanical Data | ||||

| Tensile Strength | MD | kg/cm² | D-882 | 600-900 |

| TD | 1200-1500 | |||

| Elongation | MD | % | D-882 | 100 - 150 |

| TD | 20 - 50 | |||

| Thermal Data | ||||

| Shrinkage (120⁰C/248 ⁰F,5 min) | MD | % | D-1204 | 2.0-5.0 |

| TD | 1.0-3.0 | |||

| CTM : Cosmo Test Method | MD : Machine Direction | TD : Transverse Direction | UT : Untreated Side |

| Disclaimer : The information provided above is based on COSMO FILMS LTD's conclusive tests, which are indicative only and provided as guidelines.They do not constitute a guarantee of any specific product attributes or the suitability of products for specific applications | |||

| Storage condition : Storage temperature to be maintained 25 Deg.C (+/-5 Deg C) & relative humidity 55% (+/-5%) to avoid accelerated reduction of surface treatment level. | |||

Updation Date : 2025-Sep-19