Pressure Sensitive Label Facestock Film Metallised, Top Coated (UPAi)

HST-2(UPAi) MO HG

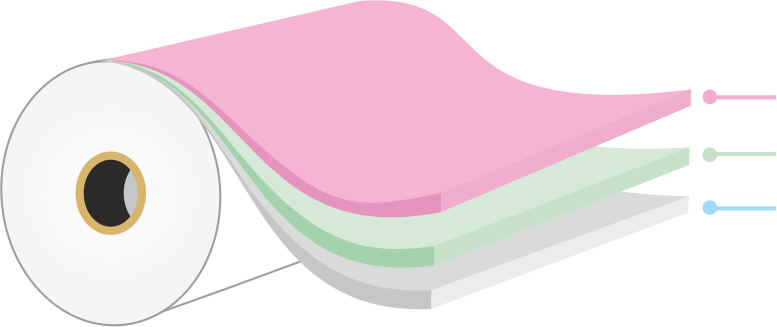

Structure

Coated print receptive layer

OPP core

Metallised layer

Description

It is a co-extruded,one side coated for print receptivity and other side metallised Bi-axially oriented polypropylene film.

Features

- Sparkling metallic appearance

- Coated print surface for excellent ink adhesion and high speed press performance

- Wide compatibility with ink system (UV, water based etc.)

- Spectacular print performance across wide variety of printing process (flexography, offset, silkscreen and hot or cold foiling etc.)

- High stiffness for conversion and dispensing

- Superior performance of print surface in humid enviornment

Applications

- Film suitable for label stock conversions

- After conversion used for pressure sensitive labels for beverages,health,beauty and pjarmaceutical application

Typical values

| Properties | Ref. | Units | ASTM#/ Test Method | HST-2(UPAi) MO HG |

|---|

| Physical Data | ||||

| Average Thickness | Micron | D-374-C | 51 | |

| Gauge | 204 | |||

| Mils | 2.0 | |||

| Thickness Variation | %(±) | 3 | ||

| Average substance | g/m² | 45.8 | ||

| Yield | m²/Kg | D-4321 | 21.8 | |

| in²/lb | 15326 | |||

| Optical Data | ||||

| Optical Density | CTM | 2.0-2.3 | ||

| Mechanical Data | ||||

| Tensile Strength | MD | kg/cm² | D-882 | 1100-1400 |

| TD | 2400-2800 | |||

| Elongation | MD | % | D-882 | 140-200 |

| TD | 30-70 | |||

| Thermal Data | ||||

| Shrinkage (120⁰C/248 ⁰F,5 min) | MD | % | D-1204 | 2.0-4.0 |

| TD | 1.0-3.0 | |||

| CTM : Cosmo Test Method | MD : Machine Direction | TD : Transverse Direction |

| Disclaimer : The information provided above is based on COSMO FILMS LTD's conclusive tests, which are indicative only and provided as guidelines.They do not constitute a guarantee of any specific product attributes or the suitability of products for specific applications | ||

Updation Date : 2022-Aug-25