Love to hear from you!

Get in touch.

Cosmo Capacitor Films, a business of Cosmo Films operating under the umbrella of Cosmo First Limited, is a renowned player in the BOPP-based films in Delhi, India. With a rich legacy spanning over 42 years, we specialize in manufacturing high-quality capacitor films. Despite being relatively new in the capacitor sector, our venture boasts state-of-the-art infrastructure and a deep technical understanding, ensuring top-notch quality and innovation in our products. Our manufacturing facility boasts an expansive carpet area, showcasing the undeniable prowess of Cosmo Capacitor Films in terms of production capacity. We take pride in our advanced technology and a skilled workforce dedicated to various core functions such as manufacturing, quality control, production, inspection, procurement, marketing, and servicing. This collective expertise positions us as an excellent force capable of delivering high-capacity metallized films to meet the evolving needs of the capacitor industry. As a global player, we extend our reach to export markets worldwide, underscoring our commitment to excellence in R&D, manufacturing, and testing facilities. Cosmo Capacitor Films is sure to emerge as a market leader, setting new benchmarks in capacitor films.

High Insulation Resistance

Wide Temperature Range

High Breakdown Voltage

High Dielectric Strength

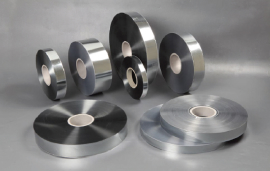

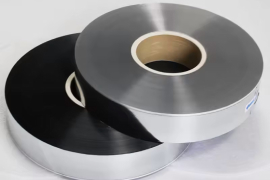

COSMO SUPER Capacitor grade Metallized Polypropylene Films

Excellent Self-Healing Properties

Various range of Film Thickness and Customizable Reel Width

Special Film Profile & Metallization

Excellent Self-Healing Properties

Various range of Film Thickness and Customizable Reel Width

Special Film Profile & Metallization

Cosmo Films has been delivering premium films for over 40+ years

Cosmo with its global presence sells in 100+ countries to a diversified customer base across various industries

Committed to superior service, Cosmo Films features a dedicated account management team

Proudly situated in Waluj, Aurangabad, India, Cosmo Films boasts a cutting-edge plant

Employing advanced technology, Cosmo Films manufactures high-quality metallized films for capacitors

Staffed with experienced professionals from Metallized Polypropylene film and capacitor industries, with 5+ to 20+ years of expertise

Our metallizer is designed with a substantial capacity of 900 metric tons per year. Additionally, we are diligently preparing for the forthcoming launch of our second metallizer, a testament to our commitment to advancing technological capabilities in film production.

The Latest Advancement In Technology For Film Metallization Is A Cutting-edge Metallization Machine

State-of-the-art Micro Slitting Machinery Featuring Advanced Technology

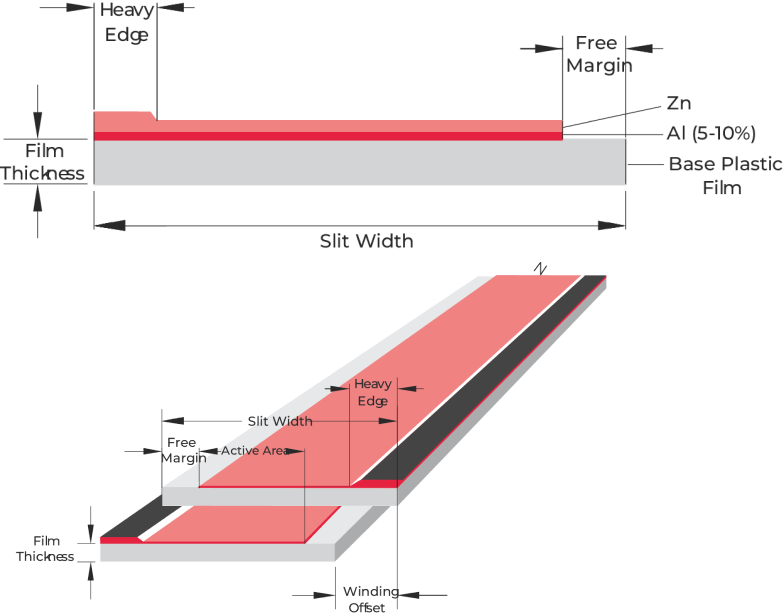

AL-ZN Standard Metallised Polypropylene Film

Application

Fan Capacitors, Motor Run/Start Capacitors, Washing Machine Capacitors, Air Conditioning Capacitors

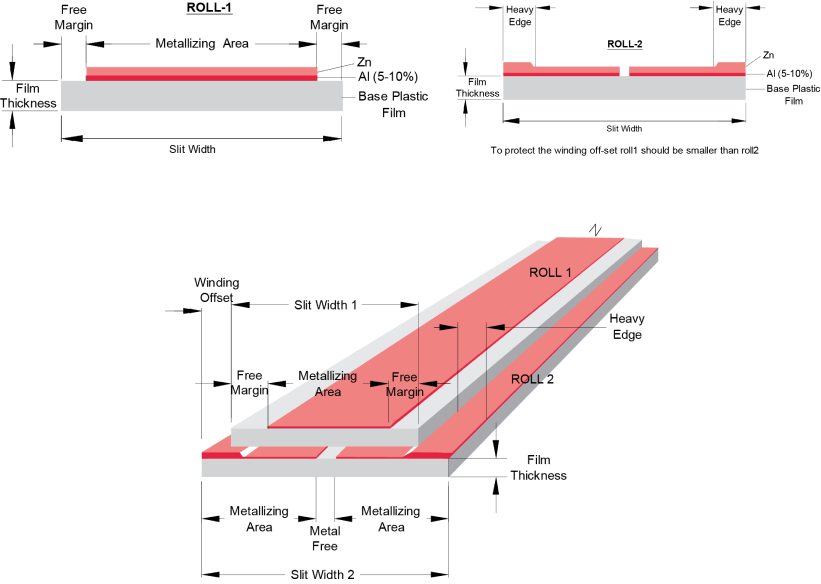

Structure

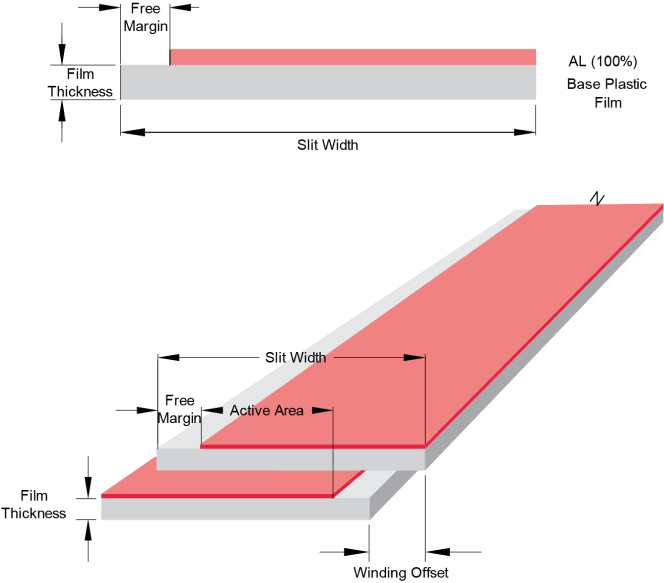

Pure AL Metallized Polypropylene Film

Application

Lighting Capacitors, Lighting Fixtures , HID Lamp Fixtures, Street Lights etc.

Structure

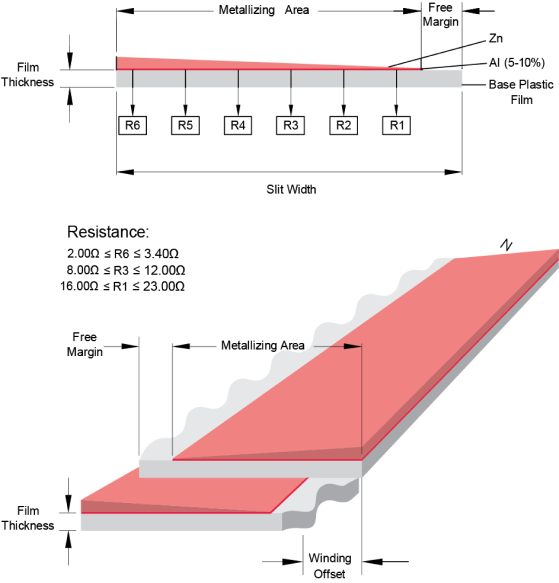

AL-ZN SLOPE / RMF Metallised Polypropylene Film

Application

APFC Control panels, Wind turbines, Welding units, Heavy Duty Industrial panels etc

Structure

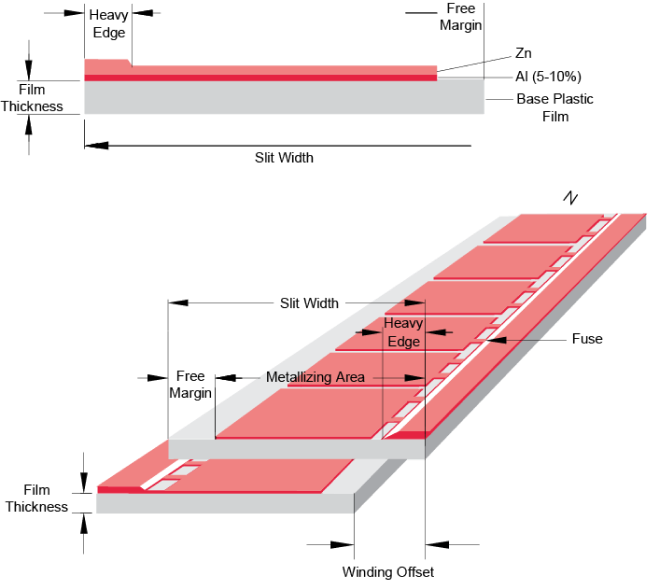

AL-ZN Segmented Metallised Polypropylene Film

Application

Power supplies, Audio amplifiers, Motor control circuits DC-DC converters, Radiofrequency (RF) circuits & etc

Structure

AL-ZN Metallised Polypropylene Film (series)

Application

Variable Frequency Drives, Renewable energy inverters,Uninterruptible Power Supplies, Electric vehicle

Structure

At our testing facility, we ensure that all capacitors manufactured undergo rigorous electric testing as per the relevant national and international standards (such as IS, IEC, UL, ISI). These tests, outlined in the specifications (ISCAP) of each product, are meticulously conducted to uphold quality standards. Capacitors that pass the electrical tests are appropriately identified to prevent any mixing with untested or rejected capacitors.

Love to hear from you!

Get in touch.