Love to hear from you!

Get in touch.

Introduction

Being human, sometimes it’s hard to identify the

changes and impact the printing industry has brought into our everyday life.

The Purpose of printing is to exchange information with the recipient and make

them aware and educated about the Purpose and functionality of the product or service.

Similarly when we talk about how critical it is if we find ourselves without daily exposure to DTP Films in our everyday life.

Starting from the courier & e-commerce bag we receive until we check in successfully at the airport. The DTP Film has been playing a significant role.

How are DTP Films Made?

A Cosmo DTP film is a BOPP-based film which has a

proprietary Active coating followed by a protective top coating, which prevents

the active coat from damage & helps to increase the print life. The film,

thus, offers resistance to water, humidity, oil & solvent.

How does DTP Film are Printed?

DTP films are printed on a thermal printer. An

active coating layer which enables a dark image/impression formation upon

contact with the print head of the thermal printer.

The DTP film is used in tagging and labelling applications where detailed printing is unnecessary. It can also be suitable for UV & water-based flexo printing.

Applications Spectrum of the Cosmo DTP

Films

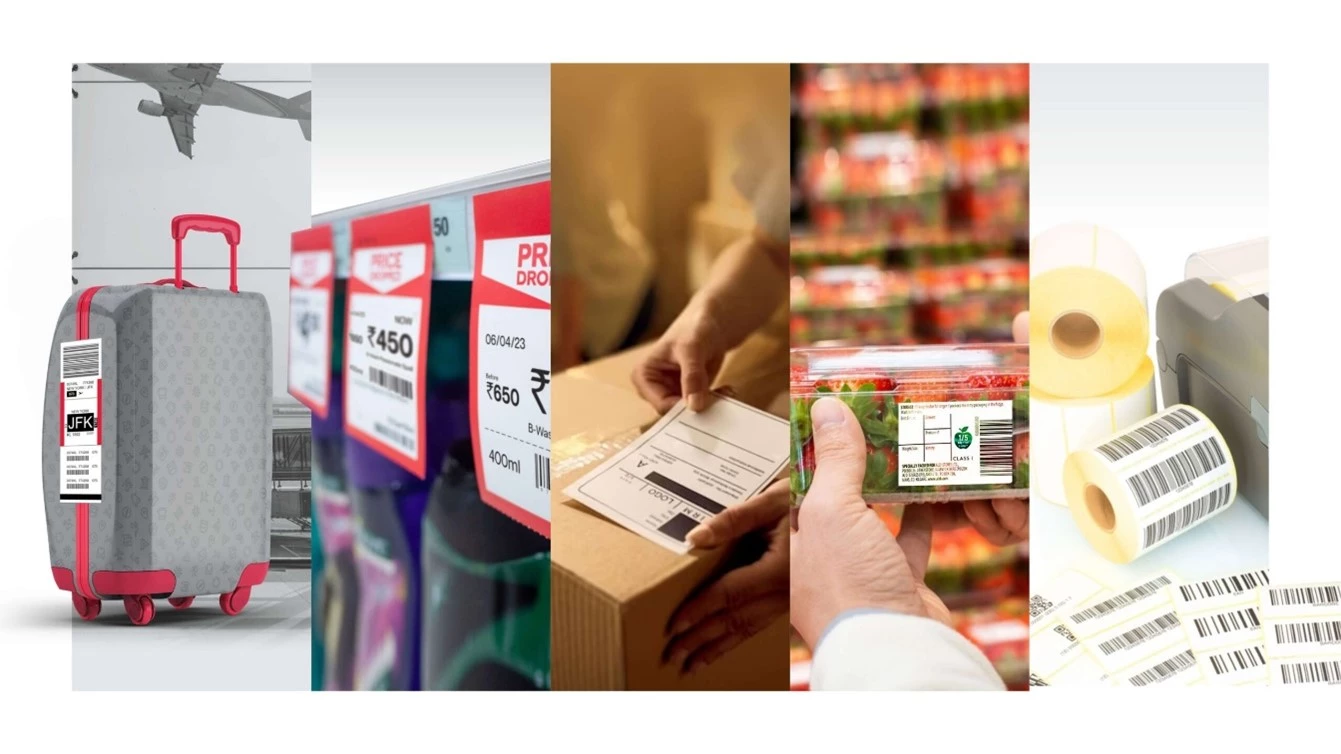

Though DTP Films have a vast application spectrum

in this world, Cosmo DTP Films are quite an excellent product to deliver

exceptional results for the below-mentioned applications.

Airline Baggage Tags | Ready-made Food Labels | Industrial Barcode Applications | Retail Price Marking | Logistics Labels | E-commerce & Courier Labels | Fruits, Vegetable & Meat Labels. The printing is done only for critical information like Barcodes, QR Codes, etc.

Simpler the Printing Process, Lesser

the Inventory Management

Cosmo DTP Film goes soft on the inventory. You

don’t need the additional items such as ribbons, ink, or toners

the companies need to order the DTP Label Stocks

required for their work. This makes the complete procurement process much more

straightforward and streamlined, resulting in reduced warehouse & stock

keeping costs.

Cosmo DTP Films are available in Roll Form.

Connect with us to Explore the abundance of advantages of DTP Films.

Featured Post

Love to hear from you!

Get in touch.